Forging is a vital process in the manufacturing of parts for heavy machinery. It involves shaping metal using localized compressive forces. The process results in parts that are stronger and more reliable than those made through other methods. This is especially important in heavy machinery, where durability and strength are crucial. Free forging parts for heavy machinery are an essential component in various industries, ensuring that equipment can withstand the rigorous demands placed upon it.

The benefits of using free forging parts in heavy machinery are numerous. Firstly, the strength of forged parts is unparalleled. The process aligns the grain structure of the metal, enhancing its mechanical properties. This makes the parts more resistant to fatigue and wear, which is crucial in heavy machinery applications. Secondly, the reliability of forged parts is well-documented. They are less likely to fail under stress, reducing the risk of costly downtime and repairs. Lastly, the versatility of forging allows for the production of complex shapes that would be difficult to achieve with other manufacturing methods.

In the realm of heavy machinery, free forging parts play a pivotal role in maintaining operational efficiency. The construction industry, for example, relies heavily on machinery with forged components. Cranes, bulldozers, and excavators all benefit from the enhanced strength and durability that forging provides. Similarly, the mining industry depends on heavy machinery to extract valuable resources from the earth. Forged parts ensure that this equipment can operate in harsh conditions without succumbing to wear and tear.

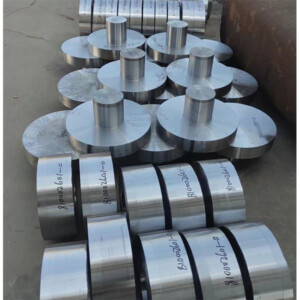

The production of free forging parts for heavy machinery involves several key steps. Initially, a billet of metal is heated to a high temperature, making it malleable. This billet is then placed between two dies and subjected to compressive forces. The metal is shaped as it is squeezed between the dies, resulting in a part that matches the desired specifications. The final step is cooling and finishing, which may include machining or heat treatment to achieve the required properties.

One of the primary advantages of free forging is its ability to produce parts with superior mechanical properties. The process results in a refined grain structure, which enhances the strength and toughness of the metal. This is particularly beneficial in heavy machinery applications, where parts are subjected to high loads and stresses. Additionally, forged parts are known for their excellent impact resistance, making them ideal for use in demanding environments.

The use of free forging parts in heavy machinery is not limited to any specific industry. From agriculture to aerospace, forged components are integral to the performance and longevity of equipment. In the agricultural sector, tractors and other machinery rely on forged parts for their robustness and reliability. In aerospace, the precision and strength of forged components are crucial for the safety and efficiency of aircraft.

The environmental impact of manufacturing processes is a growing concern for many industries. Free forging offers several advantages in this regard. The process is energy-efficient, as it requires less material and energy compared to other methods. Additionally, forged parts have a longer lifespan, reducing the need for frequent replacements and minimizing waste. This makes free forging an environmentally friendly choice for producing heavy machinery parts.

Quality control is a critical aspect of producing free forging parts for heavy machinery. Manufacturers employ a range of techniques to ensure that each part meets the required standards. Non-destructive testing methods, such as ultrasonic and magnetic particle inspection, are commonly used to detect any defects in the metal. Additionally, rigorous dimensional checks are performed to verify that the parts conform to the specified tolerances.

The cost-effectiveness of free forging is another significant advantage. While the initial setup costs may be higher than other manufacturing methods, the long-term benefits often outweigh these expenses. Forged parts are more durable and reliable, reducing maintenance and replacement costs. Furthermore, the ability to produce complex shapes with minimal material waste can result in significant cost savings for manufacturers.

Innovation in forging technology continues to drive improvements in the production of free forging parts for heavy machinery. Advances in materials science have led to the development of new alloys with enhanced properties. Additionally, modern forging techniques, such as computer-controlled processes, allow for greater precision and efficiency. These innovations are helping to push the boundaries of what is possible in the manufacturing of heavy machinery components.

The global demand for heavy machinery is increasing, driven by growth in construction, mining, and other industries. As a result, the need for high-quality free forging parts is also on the rise. Manufacturers are investing in new technologies and expanding their capabilities to meet this demand. This trend is expected to continue, with the market for forged parts projected to grow significantly in the coming years.

Customization is a key benefit of free forging, allowing manufacturers to produce parts tailored to specific applications. This is particularly important in heavy machinery, where different environments and operational requirements necessitate unique solutions. By working closely with customers, manufacturers can develop forged parts that meet the exact needs of each application, ensuring optimal performance and longevity.

The durability of free forging parts for heavy machinery is unmatched. The process results in parts with a dense, uniform structure that is resistant to cracking and deformation. This is essential in heavy machinery, where components are subjected to extreme forces and harsh conditions. The longevity of forged parts reduces the frequency of replacements, leading to lower operational costs and improved efficiency.

Free forging is a versatile process that can be used to produce a wide range of parts for heavy machinery. From gears and shafts to connecting rods and axles, forged components are found in virtually every piece of equipment. This versatility makes forging an attractive option for manufacturers looking to produce high-quality parts that can withstand the demands of heavy machinery applications.

The process of free forging is not without its challenges. Producing parts with complex geometries requires skill and precision, and maintaining consistent quality can be difficult. However, advancements in technology and manufacturing techniques are helping to overcome these challenges. By investing in state-of-the-art equipment and training skilled workers, manufacturers can produce free forging parts that meet the highest standards of quality and performance.

Safety is a top priority in the production of free forging parts for heavy machinery. Manufacturers adhere to strict safety protocols to protect workers and ensure the integrity of the parts. This includes regular maintenance of equipment, proper handling of materials, and comprehensive training for employees. By prioritizing safety, manufacturers can prevent accidents and produce parts that are safe and reliable for use in heavy machinery.

The future of free forging in the heavy machinery industry looks promising. As demand for durable and reliable components continues to grow, manufacturers are exploring new materials and techniques to enhance the properties of forged parts. Additionally, the trend towards automation and digitalization is transforming the forging process, allowing for greater precision and efficiency. These developments are set to drive further innovation in the industry.

Education and training are crucial for the continued success of the free forging industry. As technology evolves, workers must be equipped with the skills and knowledge needed to operate advanced machinery and produce high-quality parts. Many manufacturers offer training programs and apprenticeships to develop the next generation of skilled workers. By investing in education, the industry can ensure a steady supply of qualified professionals to meet future demand.

Collaborations between manufacturers and research institutions are driving advancements in the free forging industry. By working together, these entities can develop new materials and processes that enhance the performance and efficiency of forged parts. This collaboration is essential for staying competitive in the global market and meeting the evolving needs of the heavy machinery industry.

In conclusion, free forging parts for heavy machinery are an indispensable component of modern industry. Their strength, durability, and versatility make them ideal for a wide range of applications. As technology continues to advance, the potential for innovation in the forging industry is vast. By embracing new materials and techniques, manufacturers can continue to produce high-quality parts that meet the demands of heavy machinery applications.

Yantai Haoyi (Shengteng) Forging Co., Ltd.우리의 핵심 팀은 2012 년부터 위조 산업을 전문으로하고 있습니다.2018 년에는 국제 무역 기능을 향상시키기 위해 상당한 업그레이드를 받았으며, 고품질의 단조 제품 및 가공 서비스를 전 세계 고객에게 제공하는 데 전념했습니다.

Copyright © 2025 Yantai Haoyi (Shengteng) Forging Co., Ltd 판권 소유.